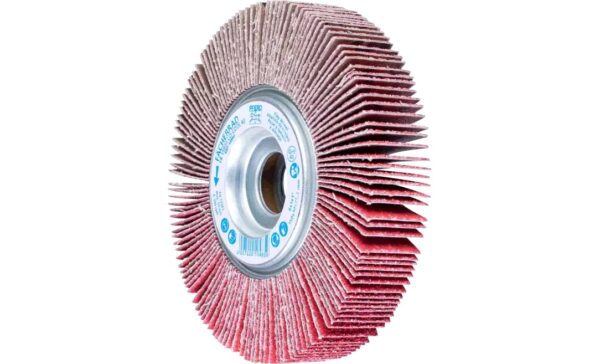

Description

On unmounted flap wheels, the flaps of coated abrasives are arranged radially around the tool axis in a fan like structure. Their flexibility enables them to adapt perfectly to the contours of the workpiece.

Depth: 100mm, 150mm, 165mm, 200mm, 250mm

Thickness: 20mm, 30mm, 50mm

Abrasive type: Aluminium Oxide, Ceramic

Cooling Additives Available - Active grinding additives in the coating substantially improve the stock removal rate, prevent clogging and result in cooler grinding.

Grits: 40, 60, 80, 120, 150, 240, 320

Bore size: 25.4mm, 44mm, M14

Materials that can be worked:

- Aluminium

- Bronze

- Other non-ferrous metals

- Hard non-ferrous metal

- Stainless steel (INOX)

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Grey/nodular cast iron (GG/GJL, GGG/GJS)

- Cobalt-based alloys

- High-temperature-resistant materials

- Copper

- Soft non-ferrous metal

- Brass

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

- Steel materials with a hardness over 54 HRC

- Steel

- Annealed cast iron

- Titanium

Applications:

- Weld dressing

- Deburring

- Surface work

- Weld dressing

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

- Angle grinder

- Cordless angle grinder

Reviews

There are no reviews yet.